Our Tooling Workshop

|

Since Hamsan was established, we have been manufacturing injection molds for export all over the world and also for customers who want to produce parts in our factory in China. We specialize in producing high-quality tooling, high-volume tooling, low-volume tooling, and 2K/insert molding. However, if our customers request prototype/low-volume tooling we can meet the demands as well. We can produce 30 sets of tools per month. Up to 390 sets per year. The largest size of mold can reach 20 tons. HIGH VOLUME TOOLS We manufacture tools that can produce millions of parts to run mass production. We can make tools up to 20 tons in size. We can also provide tools that do not require such a high volume of production. LOW VOLUME TOOLS Prototype tooling is becoming more and more of a demand in recent years. We make these types of tools for our customers to validate the design and part function before moving into mass-production tooling. 2K/INSERT MOLDING We are very experienced in applying this technology to over-mold thermoplastic onto metal core and 2K injection molding. The components we produce are largely used in automotive and industrial products. |

|

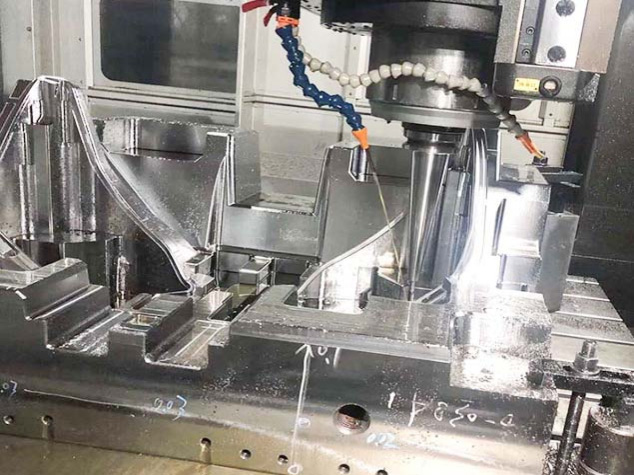

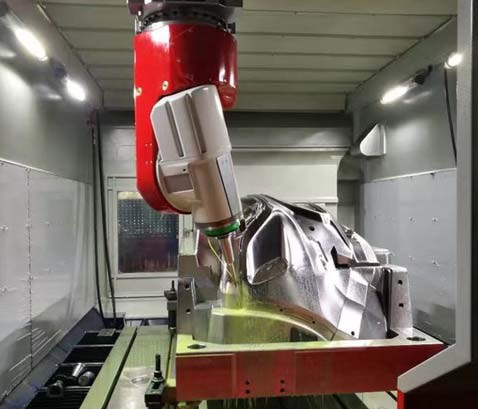

Precision CNC Machine Center

|

We are an international provider of high‐quality CNC machining services, CNC Milling and CNC Turning. We have sophisticated three‐axis, five‐axis, and turning‐milling compound equipment. Coupled with the latest technical support, we can manufacture high‐precision customized parts; we are good at cost control and processing of special‐shaped products, and can quickly deliver the parts required by customers. Precise cuts and a wide range of material options make CNC machining the preferred solution for prototyping and low‐volume manufacturing. |

Slow Feeding Wire Cut

|

The wire cut department is equipped with one set of Sodick WEDM machines. The general precision is 0.005mm. We also have a source for 5 sets of Seibu wire‐cut machines and 2 sets of Sodick oil wire‐cut machines. The wire cut precision can be within 0.001mm, the smallest wire used is 0.03mm and the smallest hole cut can be 0.12mm Sodick wire‐cut EDM Sodick wire‐cut EDM |

|

Mirror EDM Machine

|

Equipped with Sodick EDM machines imported from Japan, we are able to handle basic EDM precision is +/‐0.005mm and the highest precision can be within 0.003mm. EDM surface smoothness can be within 2um and corner clearance within R0.015mm if required. |

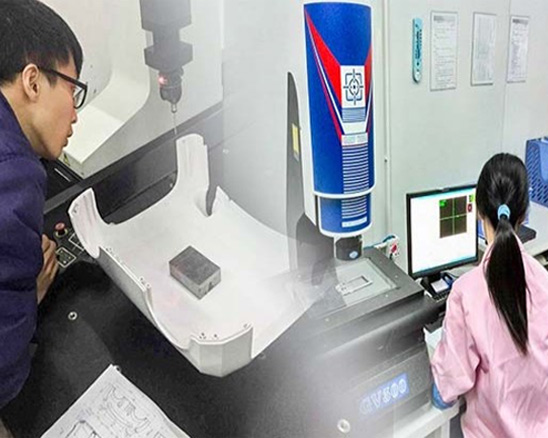

QC Department

Take quality as root, our products are inspected at every stage throughout the tooling process including drawing auditing, copper electrode, CNC, EDM, EDW, Fitting check before trialing the tooling, and pre‐shipment check, in addition, we can provide customers with FAI, GR&R, MSA, CPK and SPC reports. Strict quality management ensures the high quality of our products that meets or even exceed customers’ requirements. |

|

What Is Plastic Injection Molding?

|

In-house plastic injection molding and rapid prototyping service Plastic injection molding involves melting plastic (in the form of pellets) into a malleable form and injecting the plastic under pressure into a mold, which forms the final product. The molds are often made of steel (hardened or pre‐hardened), aluminum, or beryllium‐copper alloy. • Injection molding machines in house from 90-ton to 400 ton • No MOQ request, you even can start from 1pcs • Quotation can be provided within 24 hours • The fastest lead time can be 3 days • Your tools are guaranteed for life in our own mold shop • 2 years free storage if no orders temporarily. Some of the plastics we design injection molds for include: ● ABS ● Nylon ● Polycarbonate ● Polypropylene ● Polystyrene ● PVC ●TPE ● TPO ● Glass‐filled resins |

|

FTV & FQC Process / Delivery

|

FTV (Final Tool Validation) and FQC( Final Quality Checking ) Process to make sure all customers requirements are met and documented before tool shipment. |