Do You Suffer From Finding A Good Prototyping Partner?

- 1.Lead time too long

- 4. Mistake/mismatch make job touch

- 2. Not original manufacturer

- 5. Delivery delayed

- 3. Quality and price unstable

- 6. Bad communication

Our One Stop Prototyping Solution Makes Life Simple.

Professional engineering/manufacturing team meets diversified requirements

● Suggestion or feedback based on DFM for design optimized can be submitted when/after prototyping.

● Processing study to make sure optimized solution applied before trim.

● One stop solution from machining, finish to assembly test.

● Processing study to make sure optimized solution applied before trim.

● One stop solution from machining, finish to assembly test.

Fast response, be quick but do not hurry

● Quick and flexible operation shorten the lead time.

● 12hours offer after RFQ received, 5days delivery, 7X24H operation.

● Communication with listen well and better understanding makes right things first time.

● 12hours offer after RFQ received, 5days delivery, 7X24H operation.

● Communication with listen well and better understanding makes right things first time.

Raw material defined and certified

● Plastic or metal raw material used based on product design exactly.

● All kinds plastic, aluminum, steel available.

● Datasheet of material or COA can be provided.

● All kinds plastic, aluminum, steel available.

● Datasheet of material or COA can be provided.

100% inspected before shipping

● FAI report for each part

● Zero complain chased

● 8D report for any mistake and keep improving

● Zero complain chased

● 8D report for any mistake and keep improving

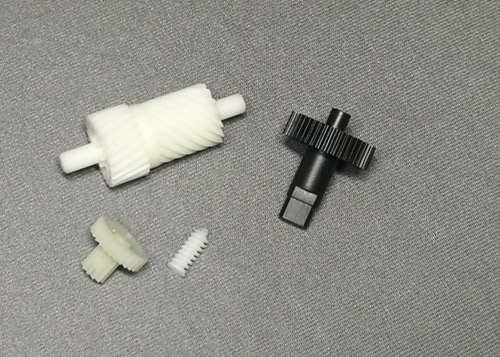

Our Prototyping Services

Our Diverse Material Options For CNC Plastic Machining

We provide a variety of precision CNC machining services that includes milling, turning and surface grinding. Whether you’re designing parts that demand high volumes or only running trials with prototypes for low-volume production, our CNC machining services are available to avail you iterative development with quick turnaround and consistency in quality.

Plastics : ●ABS ● Acrylic ● PC ● PP ● PTFE(Teflon)

Metal: ● Aluminum ● Brass ● Copper

If you require alternative materials that are not on our complete list we are glad to source them for you.

Plastics : ●ABS ● Acrylic ● PC ● PP ● PTFE(Teflon)

Metal: ● Aluminum ● Brass ● Copper

If you require alternative materials that are not on our complete list we are glad to source them for you.

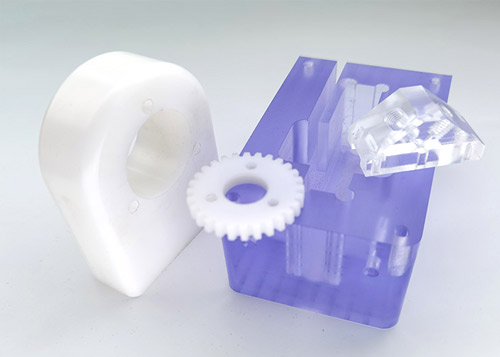

Vacuum Casting

Vacuum casting, which is using a master prototype to make a silicone mould, and then produce the reproduction via pouring the material into the silicone mould. This tech is usually used for small batches production because the cost of the silicone mould is lower than the steel mould. Also, the production lead time of vacuum casting is shorter than other process.

3D Printing

We can solve specific design or production challenges. If you want to explore how 3D printing can solve a specific design or production challenge our consultancy team is highly qualified to help. As engineers with over 20 years’ combined experience, we understand both the traditional manufacturing and additive manufacturing processes.

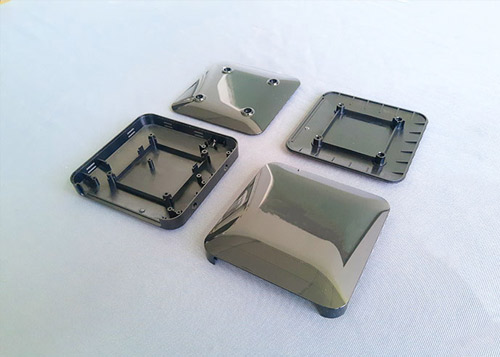

Finished Product Gallery

Hamsan’s customers come from all walks of life around the world. The processed products cover the medical equipment industry, auto parts industry, aviation and shipping industry, industrial machinery manufacturing, electronic and electrical manufacturing, fitness equipment industry,